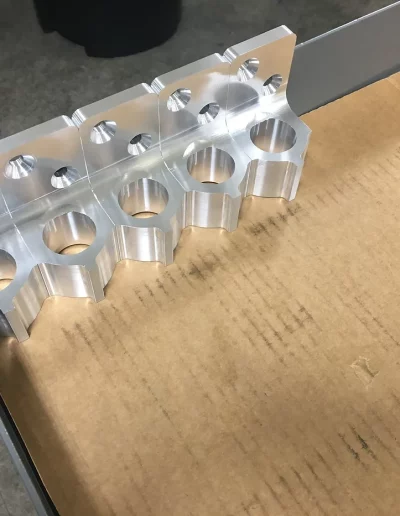

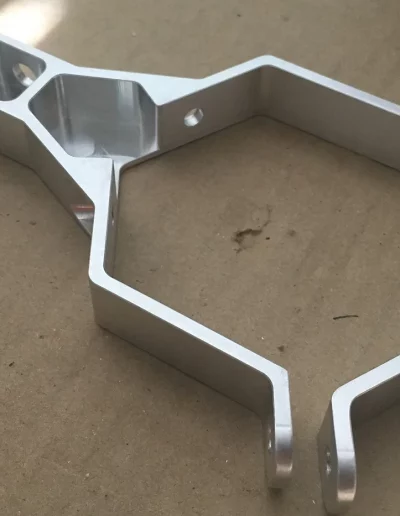

Machining

A Collaborative Process

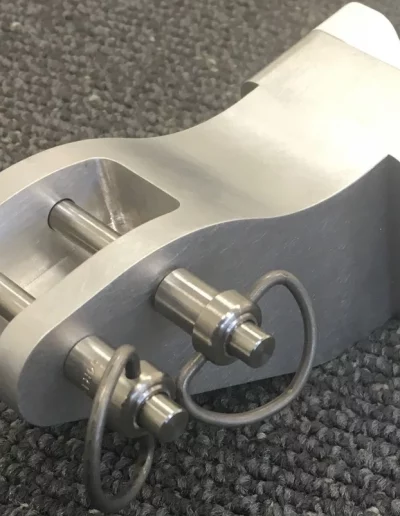

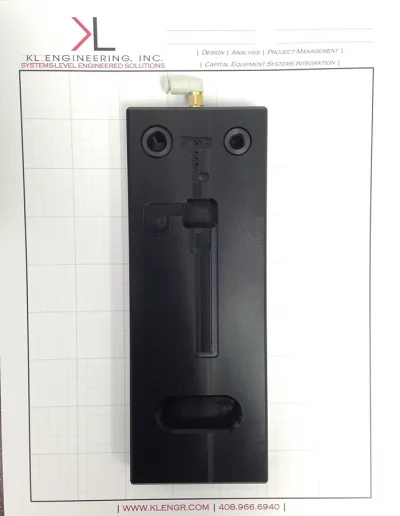

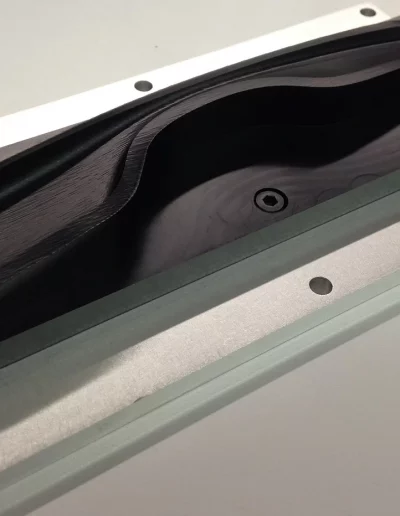

At KL Engineering, we understand your need for quality parts and that you need them quickly. We proudly service customers across numerous industries, working to develop creative solutions and generating custom parts for each unique customer. Our customer-centric approach aims at providing highly customized solutions for a wide range of applications, ensuring each client feels valued during every step of this collaborative process.

Some of the most common industries we serve are:

- Semiconductor

- Alternative energy

- Energy storage

- Telecommunications

- Aerospace

- Motorsports

- Construction

- Architectural

Contact us today to request a quote:

408.966.6940

kevin@klengr.com

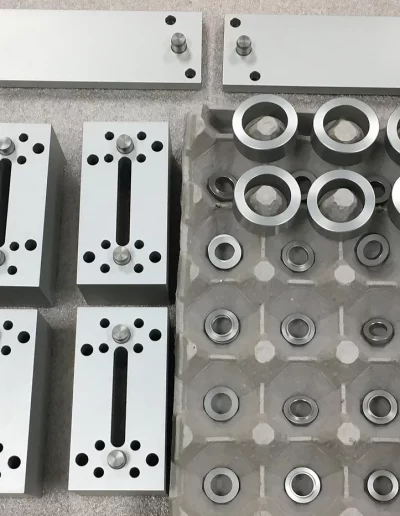

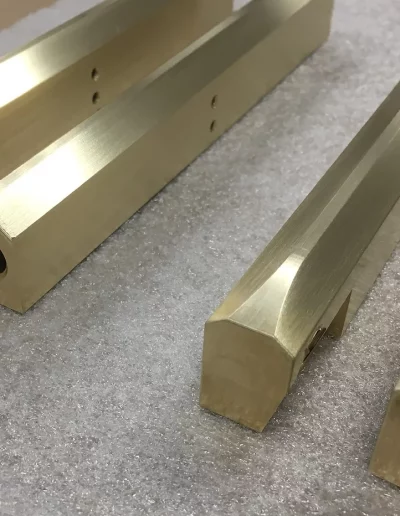

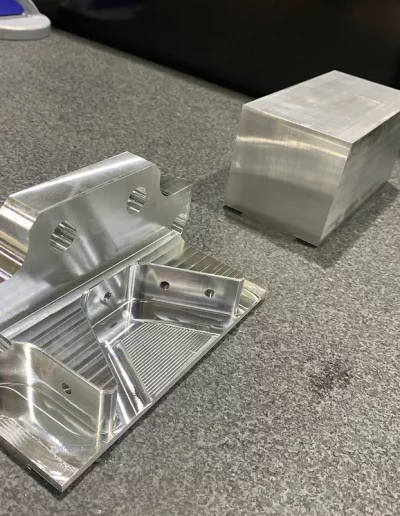

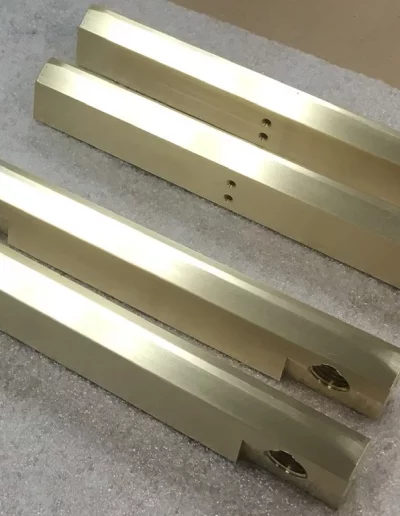

Our body of materials includes:

- Aluminum

- Steel

- Stainless steel

- Alloy

- Copper

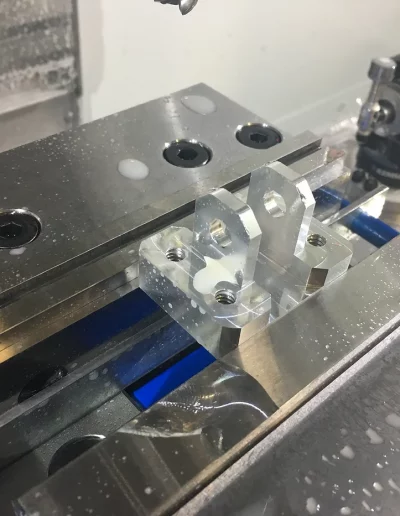

- Engineering plastics

Our Machines

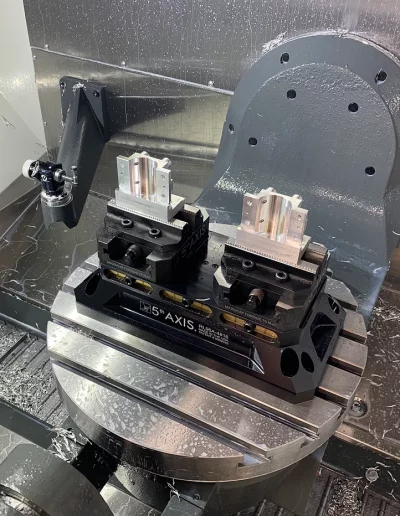

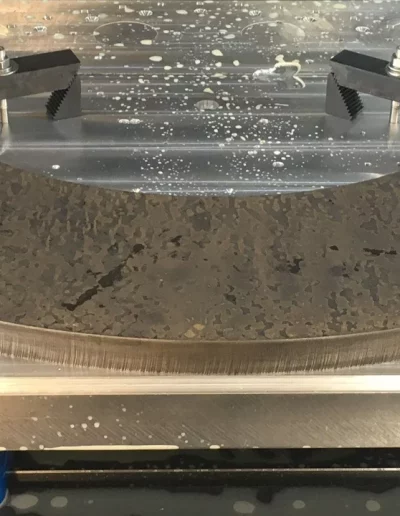

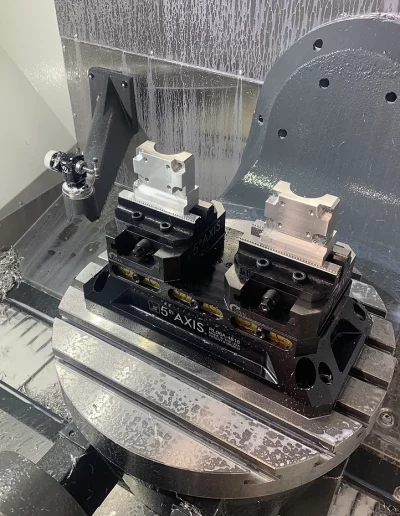

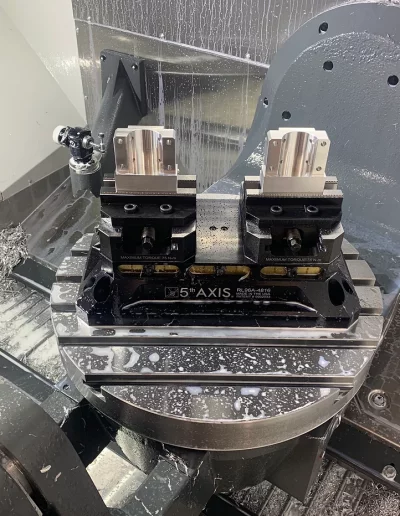

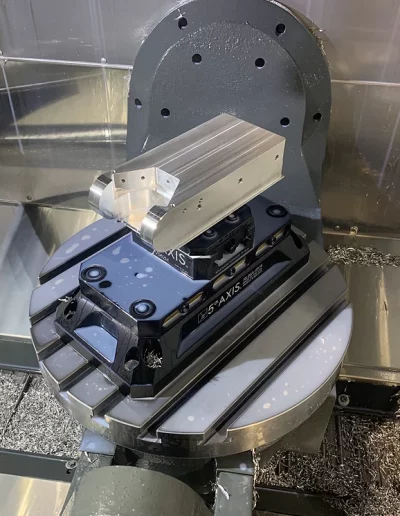

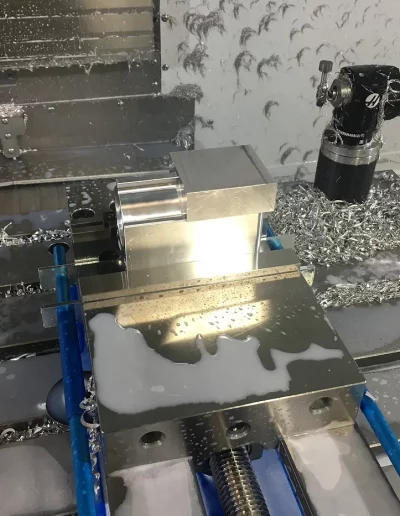

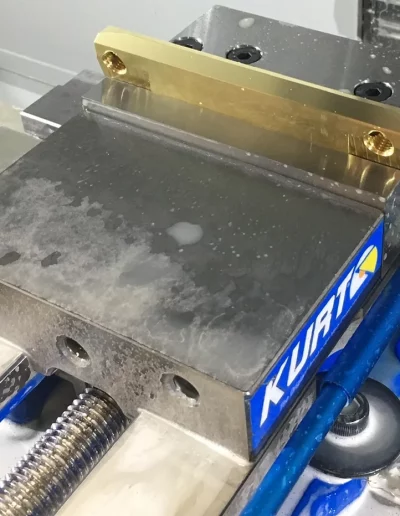

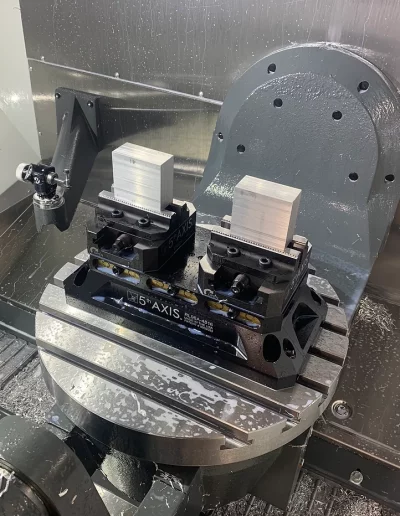

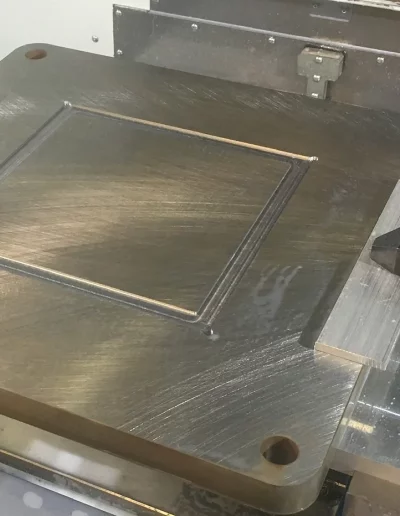

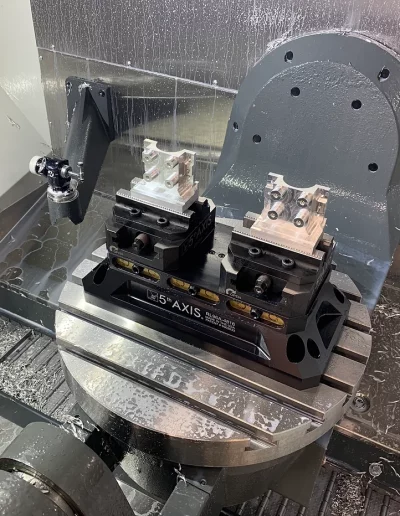

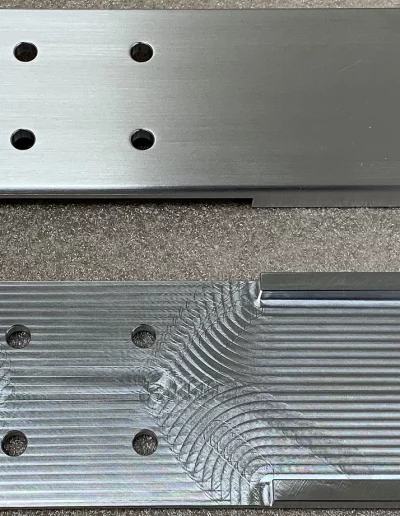

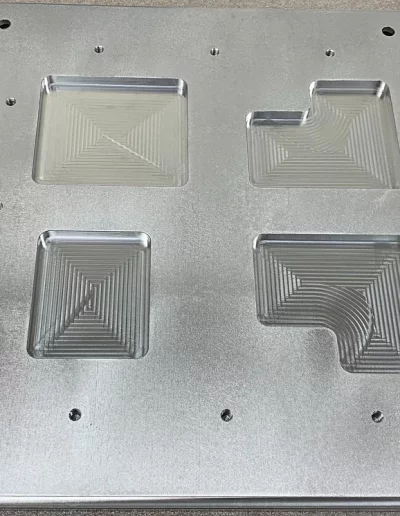

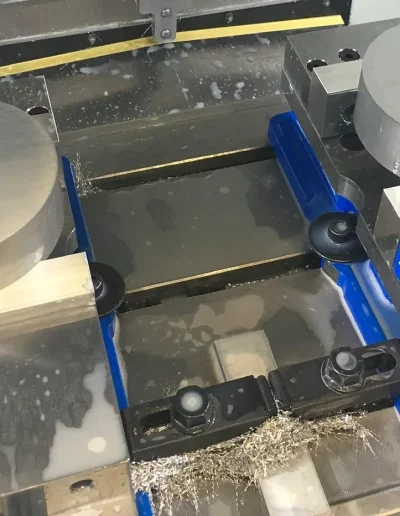

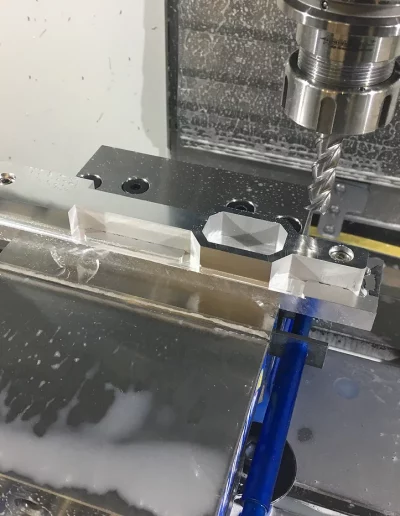

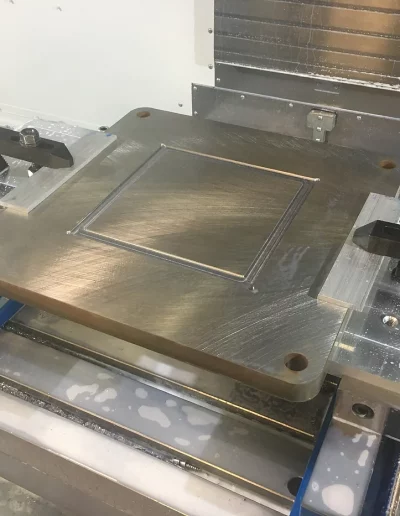

We seek to offer advanced machining capabilities, consistently working to align our customers with the most advanced and effective technologies possible. Our experienced, in-house engineering design team can design custom fit fixtures for your components. We also utilize a waterjet cutting process to prepare material for CNC machining operations to streamline the part production process.

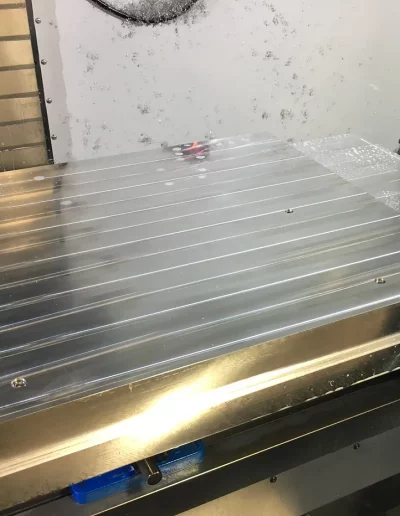

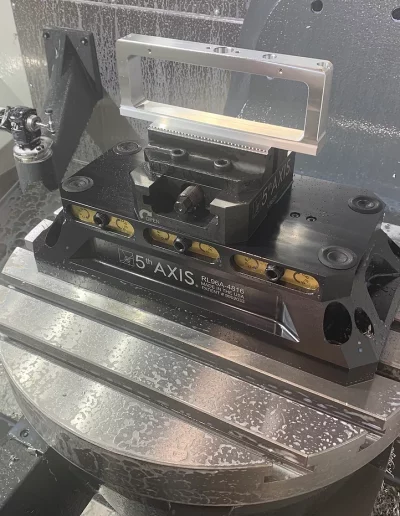

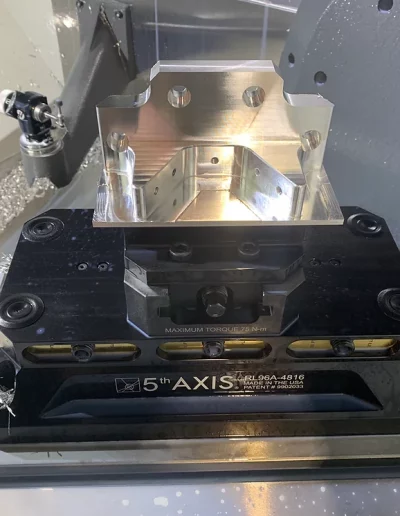

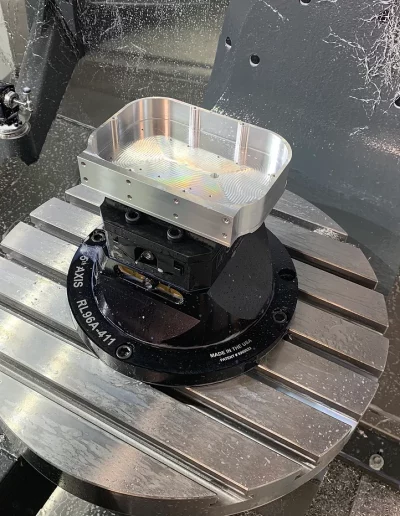

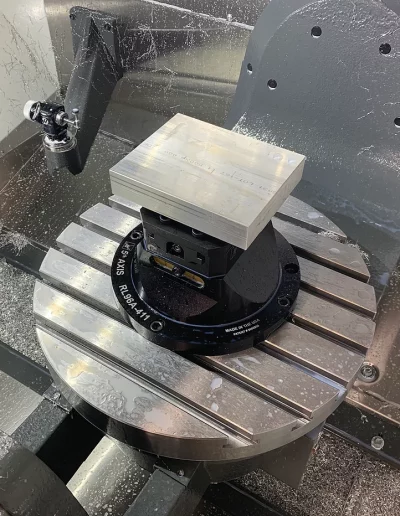

We provide a diverse variety of machining equipment, from our 5-axis machines offering minimal operator interaction and complex geometry capabilities, to our 3 and 4-axis machines, providing higher production volumes more efficiently. This equipment allows us to produce high-quality, short to medium production runs quickly. Regardless of what type of custom part you need, KL Engineering has the equipment and the expertise to guide you through the process seamlessly.

Our Machining Offerings and their Associated Specs:

CNC Milling Equipment:

Haas UMC-750ss

5-Axis – 30″ x 20″ x 20″ – X/Y/Z Travels

Haas UMC-750

5-Axis – 30″ x 20″ x 20″ – X/Y/Z Travels

Haas VF-5 w/ Rotary 4th Axis

4-Axis – 50″ x 26″ x 25″ – X/Y/Z Travels

Haas VF-2ss

3-Axis – 30″ x 16″ x 20″ – X/Y/Z Travels

CNC Turning Equipment:

Haas ST-30Y

- Y-Axis, Live-Tool Turning Center

- 3″ Thru-Bore Capacity

- Royal QG Collet Chuck & 10″ Hyd. Chuck

- Bar Feeder + Programmable Tailstock

Manual & Support Equipment:

Manual Knee Mill (Bridgeport-clone)

9×49″ w/ DRO

Manual Precision Gap Bed Engine Lathe

1440, DRO, Inch + Metric Threading

Sawcutting (Band Saw up 13″V x 18″H capacity, Cold Saw, Cutoff Saws, etc.)

Finishing – Tumbling & sanding

CAD/CAM:

- SolidWorks (4 seats)

- Autodesk HSMWorks

- Mecsoft VisualCAM